When it comes to decentralized wastewater solutions, the STEP (Septic Tank Effluent Pumping) system stands out for its efficiency, scalability, and reliability. At the heart of every STEP system lies a crucial component: the pump vault. Understanding what goes on inside the vault can help homeowners, contractors, and system designers make informed decisions about installation, maintenance, and performance.

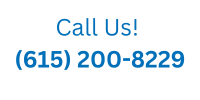

What Is a STEP Pump Vault?

A STEP pump vault is a chamber installed inside or adjacent to the septic tank that houses the pump and associated components. Its purpose is to collect and move effluent—the liquid waste that remains after solids have settled in the septic tank—to a treatment facility or shared sewer system.

Key Components Inside the Vault

Effluent Pump

The effluent pump is the workhorse of the STEP system. Located in its own chamber inside the vault, the pump activates once the effluent reaches a certain level, pushing it through a pressurized sewer line. The pump pictured here is 4″ in diameter, is submersible, and is rated for wastewater use with an emphasis on reliability and energy efficiency.

Float Switches

Two float switches are used to monitor the liquid levels inside the vault. When the liquid level rises, an electrical circuit inside the “lower” float is completed and sends power to the effluent pump. The pump will remove effluent until the water level drops and the float stops sending power to the pump. A second “upper” float triggers a high-water alarm if something goes wrong and the liquid level continues to rise. Proper float placement is critical for preventing overflows or dry runs.

Pump Vault Screen or Filter

Before liquid can enter the pump chamber, it must pass through an adjacent filter. This screen prevents suspended solids from entering the pump, which helps extend pump life and ensures cleaner flow downstream. Filters should be checked and cleaned periodically to avoid clogging.

Discharge Piping

Connected to the pump, this piping carries effluent under pressure to the next stage of treatment. It must be properly sized and sealed to maintain pressure and avoid leaks.

Electrical Connections & Control Panel

The pump and floats are wired to an external control panel, typically mounted near the tank. The panel may include circuit breakers, a manual override, and an alarm.

Why the Vault Matters

- Effluent Quality Management: A properly designed and installed pump vault ensures only clear effluent is pumped while leaving solids in the tank.

- Reliability: Pump vaults can provide years of reliable operation with minimal maintenance.

- Efficiency: Effluent pumps are an energy-efficient way to move effluent.

- Serviceability: Pump vaults are designed for easy access to pump, floats, and filter making maintenance straightforward.

Maintenance Tips

- Monitor sludge buildup in bottom of septic tank.

- Check float switches regularly for tangling or grease buildup.

- Clean effluent filters as needed.

- Test alarms and manual pump operations.

- Inspect electrical connections for corrosion.

- Educate users about what not to flush (grease, wipes, harsh chemicals).

Final Thoughts

The pump vault may be buried and out of sight, but it’s central to the performance of a STEP wastewater system. Understanding its anatomy helps ensure the system stays efficient, resilient, and worry-free for years to come. Whether you’re installing a new system or maintaining an existing one, what happens inside the vault is key to everything that flows beyond it.